Open-Cell vs. Closed-Cell: What’s the Difference?

Spray foam insulation has become one of the most popular insulation products in recent years, thanks to its versatility and performance. Widely used for tiny homes, van conversions, shipping container homes, and new suburban houses, spray foam is also gaining traction as a superior alternative to traditional insulation.

What Are Open and Closed Cell Spray Foam Insulation?

Open and closed cell spray foam are two types of polyurethane insulation, each made from two key components:

- Part A: A standard blend of reactive, low molecular weight chemicals called isocyanates.

- Part B: A proprietary blend containing polyols, catalysts, flame retardants, blowing agents, and surfactants, which vary between manufacturers.

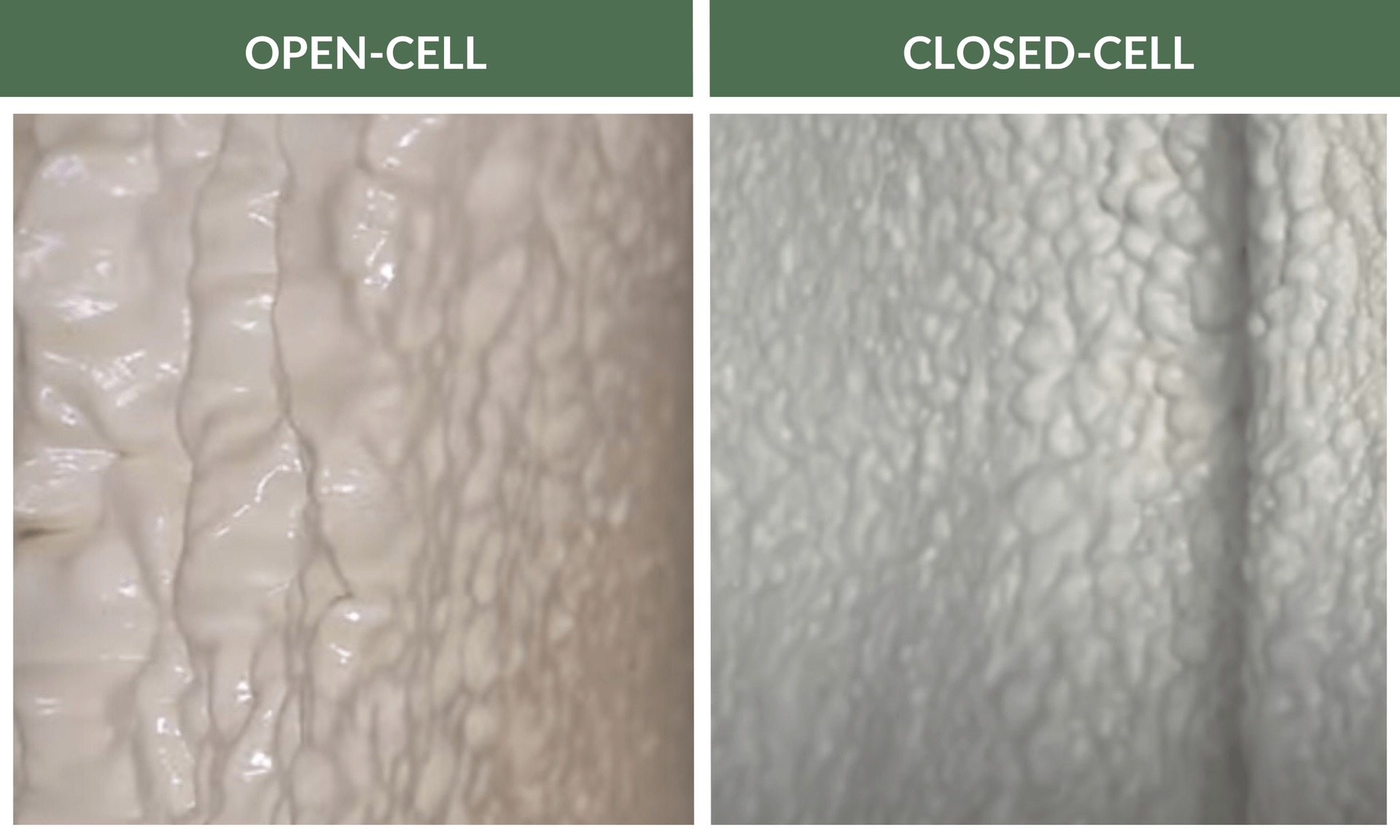

When mixed, these components undergo a chemical reaction that produces polyurethane foam. Open cell spray foam forms ruptured bubbles that create a soft, flexible material. Closed cell foam, on the other hand, forms interconnected, closed pockets filled with trapped blowing agents, resulting in a rigid, dense structure.

We will get back to you as soon as possible.

Please try again later.

Key Differences Between Open and Closed Cell Spray Foam

| Open-Cell | Closed-Cell | |

|---|---|---|

| Density & Structure | Light and flexible. It has a lower density (0.4–1.2 pounds per cubic foot), offering higher yield and greater coverage. | Dense and rigid. It has a higher density (1.75–2 pounds per cubic foot), making it more durable and better suited for structural reinforcement. |

| Expansion Rate | Expands over 100 times its liquid volume, ideal for filling nooks and crannies. | Expands 30–40 times, making it suitable for tight spaces. |

| R-Value | Provides a lower R-value of 3.5 per inch | Offers a higher R-value of 6 per inch. Making it more effective at insulating against heat transfer. |

| Moisture Resistance | Moisture-permeable, allowing water vapor to pass through and making it unsuitable for below-grade applications. | Moisture-impermeable and acts as a vapor barrier when applied at sufficient thickness (over 1.5 inches). |

Applications of Open and Closed Cell Spray Foam

- Open Cell Spray Foam:

Best for soundproofing, open cell foam is flexible and easier to work with during renovations. It performs well in warmer climates by allowing structures to dry out and preventing mold.

- Closed Cell Spray Foam:

With its rigid structure, closed cell foam is ideal for exposed walls and reinforcing exterior walls. It is better suited for colder climates due to its higher R-value and excellent moisture resistance.

Heat Transfer and Air Sealing Properties

Both open and closed cell spray foam excel at preventing heat transfer through conduction, convection, and radiation. Properly applied, they also act as air barriers, reducing air loss by 98% and outperforming traditional insulation materials.

Considerations for Use

- Cost:

Open cell spray foam typically costs $0.50–$1 per board foot, while closed cell foam costs $1.50–$3. Prices may vary based on raw material availability and supply chain conditions.

- Fire Resistance:

Both types of foam meet Class I fire standards, with a flame spread index of less than 25 and a smoke-developed index of less than 450. However, they may char and emit toxic smoke when burned.

- Environmental Impact:

Modern closed cell foam uses blowing agents with low global warming potential, addressing past concerns about environmental harm.

Making the Right Choice

Choosing between open and closed cell spray foam depends on your project requirements, budget, and climate.

Both offer significant benefits over traditional insulation but come with unique considerations.

Call us today, and we’ll guide you in evaluating your needs and selecting the best option for your property and budget.

GET YOUR FREE QUOTE TODAY!

For top-notch insulation services in Montreal and the surrounding areas, trust Spray Foam Insulation DDO! With our extensive experience, competitive pricing, and dedication to delivering exceptional results, we’re confident you won’t find a better choice. Reach out to us today to learn more about how we can provide the perfect insulation solution for your needs!

QUICK LINKS

COMPANY INFO